Modular Belts

Conveyor Belts

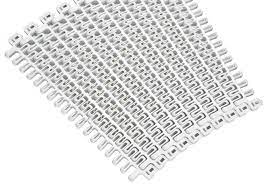

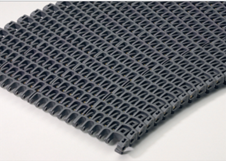

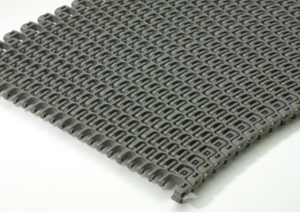

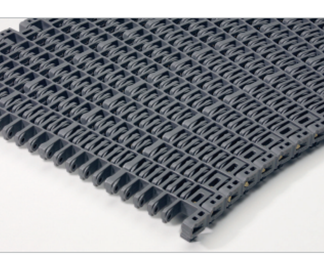

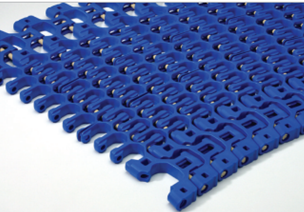

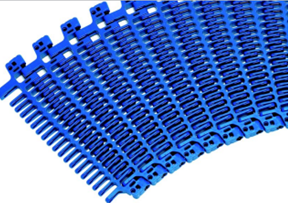

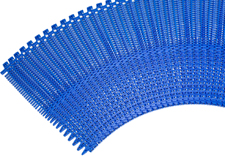

We offer a wide selection of modular conveyor belts in various plastic types, including food approved grades, to suit your specific application. Choose from our range of straight belts, KVP belts, Radius belts and Spiral belts, along with a range of accessories. We supply modular conveyor belts in various designs, including solid “flat top” belting and “flush grid” belting.

Call our helpful sales team to make a custom order for modular conveyor belting on 0117 954 1117. We’ll be happy to advise you on the best modular belting for your requirements and answer any questions you may have. We hold some of the largest stocks in the industry so there is usually no delay with the quick delivery of your modular conveyor belting, which we can send to anywhere in the UK.

Modular Conveyor Belt Repairs, Updates and Refurbishments

Provincial Rubber’s Our team of expert, highly qualified and experienced conveyor belting engineers are on hand to help with any fabrications and refurbishments you may require for your conveyor operations. Provincial Rubber’s expert conveyor engineering services are offered to businesses large and small across South and South West England, South Wales, the Midlands and the central M4 corridor from our base in Bristol.

Provincial Rubber we offer a wide range of conveyor belting services including repairs, conveyor belt servicing, belt lagging, belt shortening and belt lengthening, belt clip jointing, conveyor belt repairs, custom fabrication, audits, site surveys, vulcanising, chute lining, engineering and conveyor belt lining services.

Filtering:

Type

Other Conveyor & Transmission Belts categories

HabasitLINK M2540

Radius Flush Grid 1"

HabasitLINK M2544

Tight Radius 1"

HabasitLINK M3843

Tight Radius 1.5"

HabasitLINK M5290

Radius Flush Grid 2"

HabasitLINK M5293

Tight Radius 2"

KVP CT610

All-In-One Curved Top

KVP IS610

All-In-One 1"

KVP IS615

All-In-One

KVP IS620

All-In-One

KVP PR620

Spiral Pro

KVP PR620 SPS

Spiral Pro Small Product Surface

KVP PR620 TTR

Spiral Pro Tight Turn Radius

Extensive product selection

We pride ourselves on high-quality rubber products and maintain large stocks, so you don’t have to wait.Unparalleled product expertise

Our team of specialists offers extensive expertise to guide customers and find effective solutions to critical challenges.Outstanding customer support

We respond to inquiries promptly, ensure on-time delivery and work closely with customers to meet your unique needs.Some of the companies we supply products to: